Wire Stripper Pliers are tools specifically designed for stripping the insulation of wires. With two handles and a stripping head with openings of different sizes, it is easy to remove the insulation on the outside of a cable or wire to expose the internal wires for easy electrical connections.

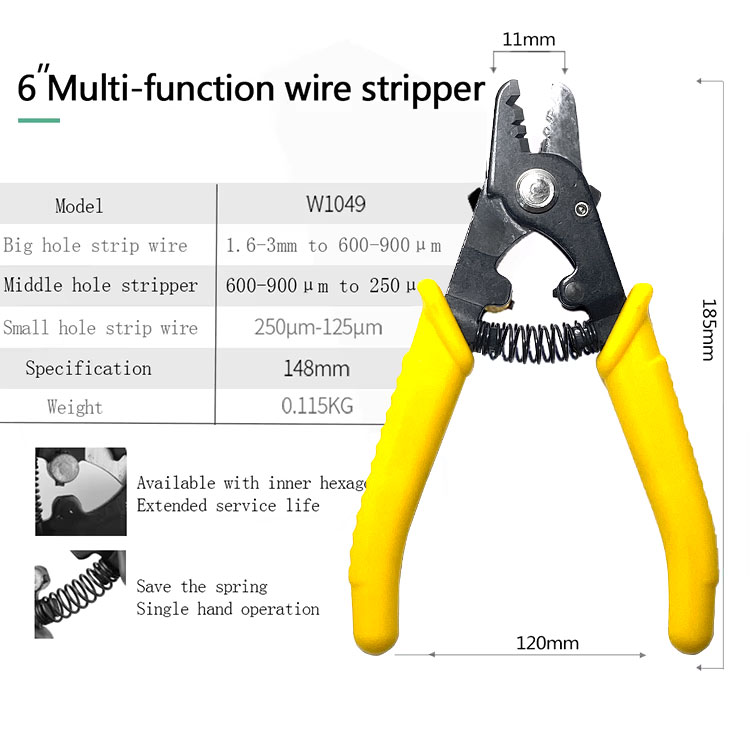

Product Details

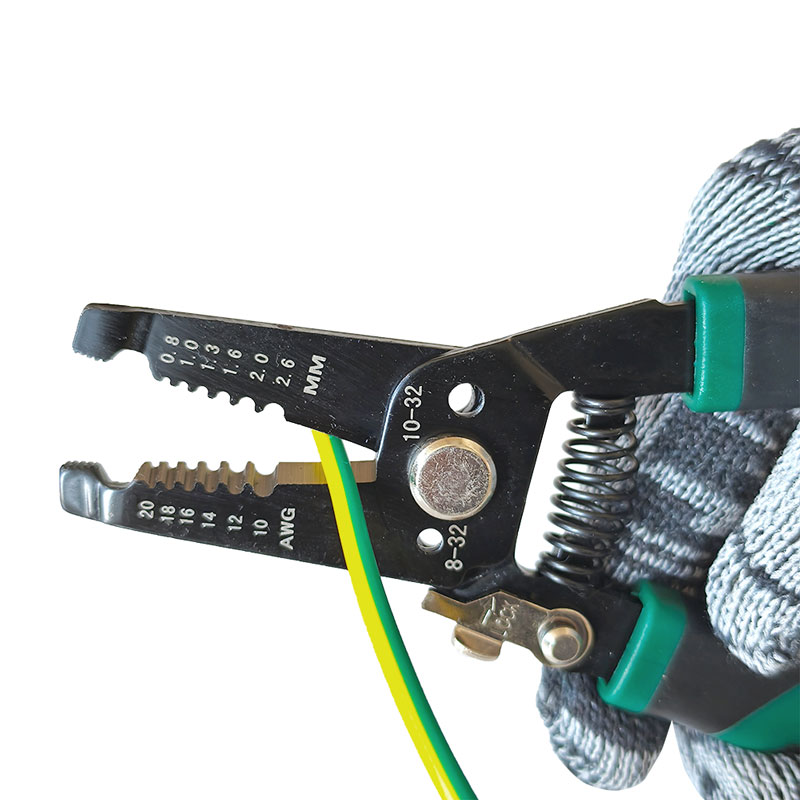

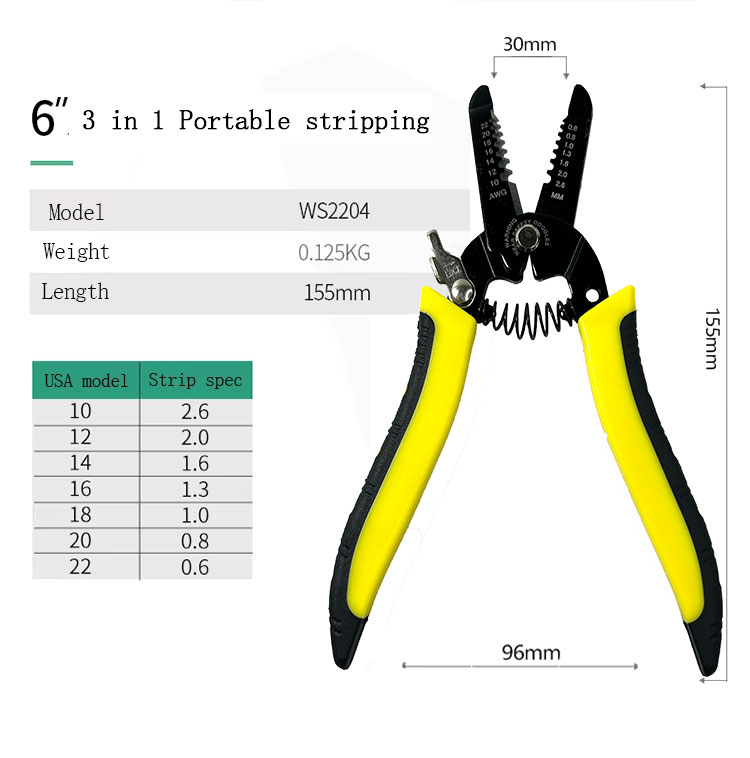

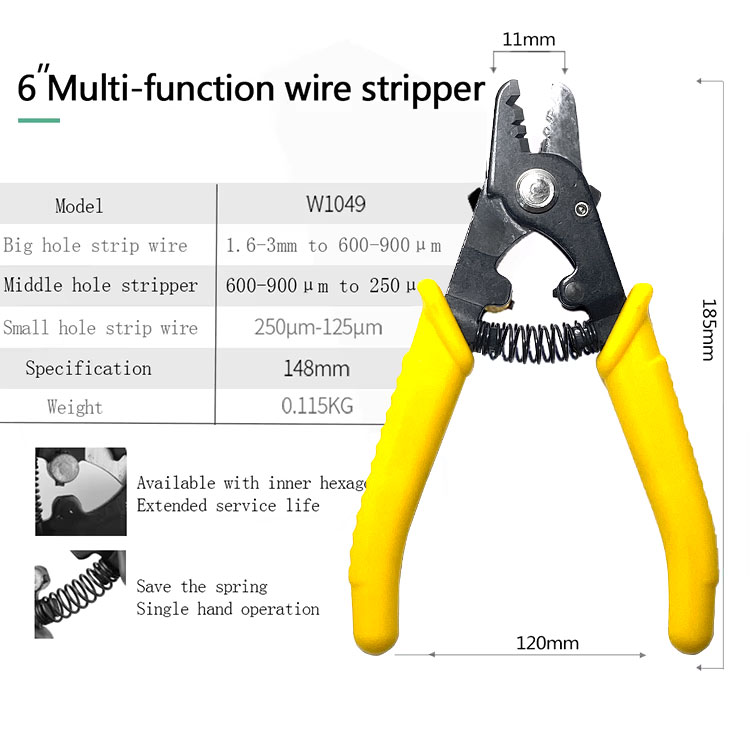

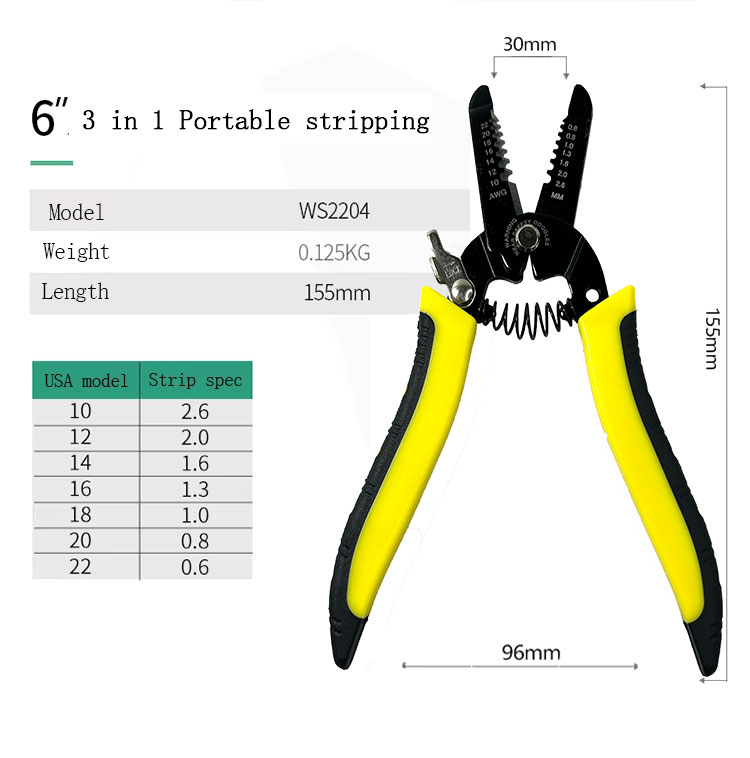

Stripping Capability: The wire stripper 10-20 AWG, can be used to cut and crimp 10-18 AWG (10/12/14/16/18) solid wire and 12-20 AWG (12/14/16/18/20) stranded wire.

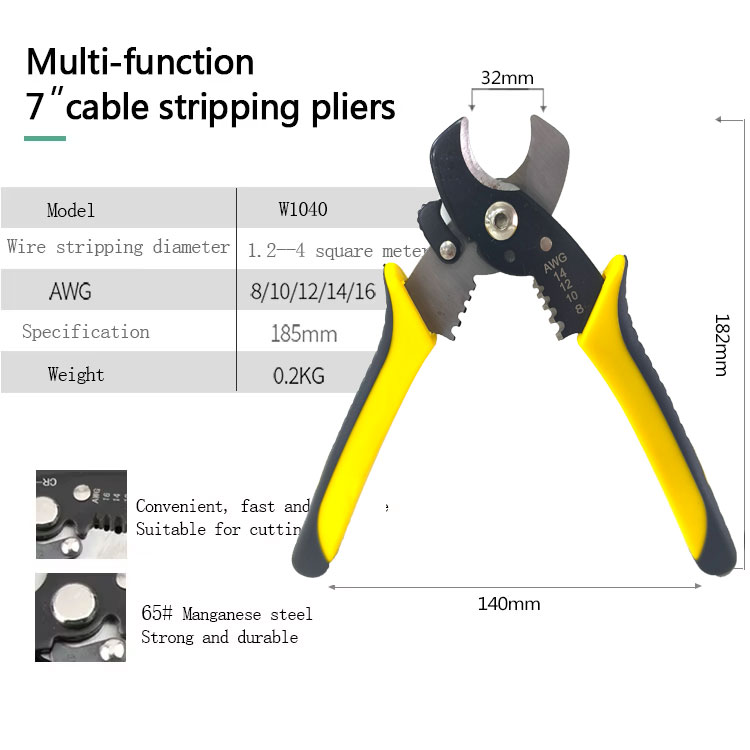

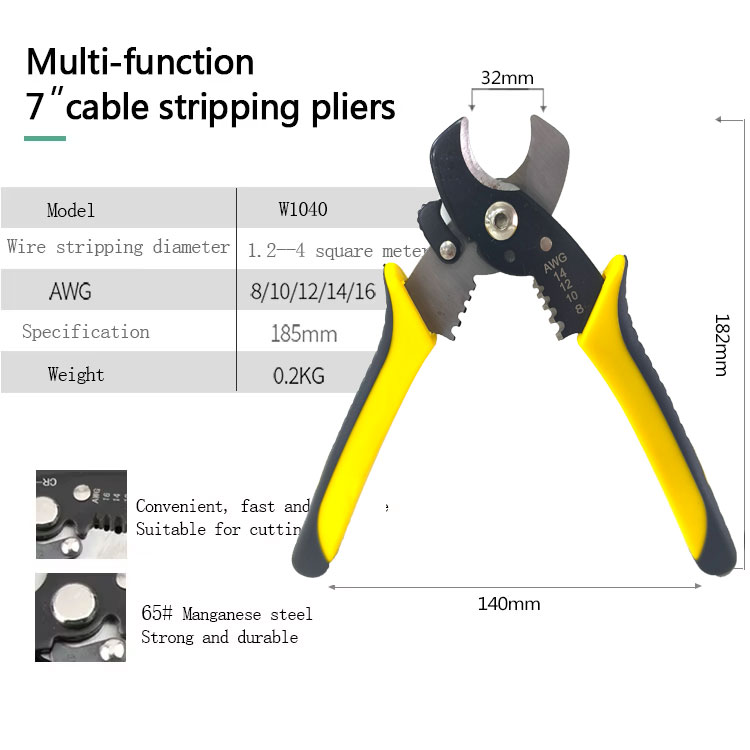

Durable Material: Made of 50# heat treated carbon steel, precision cutting molding. Glass sanding surface treatment, sharp cutting, durable, not easy to rust.

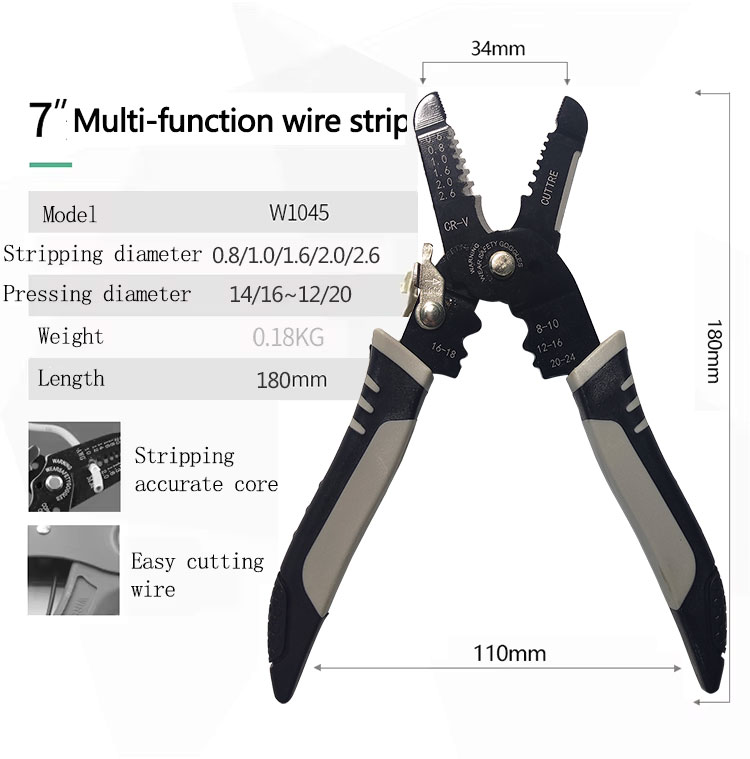

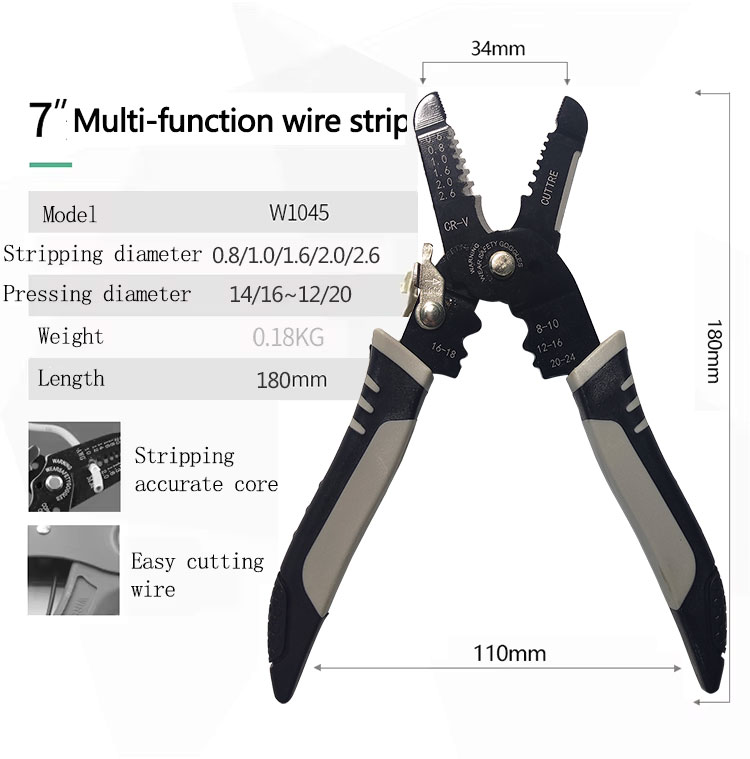

Multi-functional Use: Wire stripper can complete the stripping, cutting, clamping, insulation terminal crimping, and even thread cutting functions.

Ergonomic Grip: Designed with dipped plastic handle, firm and comfortable, spiral spring function with locking mechanism, improving efficiency and reducing fatigue.

Widely Used: Suitable for industrial, electrical and home DIY use. Ideal for stripping and crimping insulated terminals of copper wire, aluminum wire, core wire, cable, multi-core wire, and bare terminal.

Features:

Versatility: In addition to stripping, many wire strippers also have functions such as cutting and crimping, which are suitable for a variety of wire processing operations.

Precise stripping: The jaws are usually designed with stripping holes of multiple sizes to accommodate different wire diameters, ensuring that the insulation layer is cleanly stripped without damaging the internal wires.

Sturdy material: Made of high-quality steel, it has high hardness and durability, and can maintain good stripping results for a long time.

Comfortable handle: The ergonomic handle design is usually equipped with non-slip material, which is convenient for long-term operation and reduces hand fatigue.

Automatic adjustment function: Some advanced wire strippers have automatic adjustment function, which can automatically adjust the stripping force according to the thickness of the wire, which is more convenient and quick.

In electrical maintenance, Wire Stripper Pliers are a key tool that helps electricians handle wires quickly and safely.

Stripping Insulation: The main purpose of wire strippers is to accurately remove the insulation of wires to expose the wires for easy connection. Different models of wire strippers can be used for a variety of wire diameters to ensure that the stripping does not damage the internal wires, maintaining conductivity and reliability of connections.

Wiring and Repair: When repairing broken or damaged wires, wire strippers are used to strip the insulation of the damaged parts to facilitate reconnection and repair, ensuring that the circuit is unobstructed.

Wire Treatment: Wire strippers can clean and shape the ends of wires to ensure that the wires are neat and tidy, reducing the risk of short circuits and poor contact, especially in the operation of connection points such as terminal blocks or switches.

Terminal Crimping: Many wire strippers also have a crimping function, which can connect the wires to the terminals to form a solid joint. This is very convenient when terminal blocks or cable terminals are required, improving installation efficiency and connection stability.

Quick cutting and wire straightening: Wire strippers are also commonly used to quickly cut wires, allowing electricians to adjust them according to the required length. At the same time, they can organize the direction of wires, reduce clutter, improve maintenance efficiency and installation aesthetics.

Wire Stripper Pliers are key tools used in the precision processing of wires and cables in electronic equipment manufacturing.

Precision Stripping: Wire strippers are used to remove the insulation of wires, exposing the conductors for connection to circuit boards or other electronic components. Their multiple-sized stripping holes can accurately match different wire diameters, ensuring clean stripping, avoiding wire damage, and ensuring conductivity and reliability.

Connection and Soldering Preparation: During the manufacturing process, wire strippers are used to process the ends of wires to make them flat and neat for soldering. Good wire end processing ensures soldering quality and connection stability, which helps to improve the life and performance of the product.

Crimping Terminals: Many wire strippers have a crimping function to firmly connect wires and terminals. Terminal crimping is essential for the assembly of cable connections, plugs and socket components, ensuring reliable contact and a secure connection.

Wire Cutting and Length Adjustment: Wire strippers can quickly cut wires, allowing technicians to adjust the cable length as needed to meet the internal layout and space requirements of the equipment, maintaining neat and streamlined wiring.

Cable management: Wire strippers can help technicians clean and organize lines when arranging and fixing cables, reduce excessive or redundant wires, improve the neatness of internal wiring of equipment, and ensure heat dissipation and operating efficiency.

FAQ

Why do wire strippers damage wires when used?

This may be because the stripping hole size does not match, or too much force is applied. Choosing the right stripping hole and applying gentle force can effectively prevent wire damage.

Why is there residual insulation on the surface of the wire after stripping?

It may be that the jaws are not sharp enough or are not aligned with the correct stripping hole. Cleaning the jaws regularly, keeping them sharp, and carefully selecting the right hole size will help strip cleanly.

Can wire strippers be used for different types of wires?

Most wire strippers can handle copper wire, aluminum wire, and fine-core cable, but for special materials such as steel core wire, special stripping tools are required.

How to ensure that the wire is not cut when stripping?

Gently clamp the jaws and rotate the wire stripper slowly. Avoid excessive force, especially when operating with thin wires.

Why do wire strippers become blunt?

Frequent use or handling of hard materials can cause the jaws to become blunt. Cleaning the wire strippers regularly and avoiding stripping materials that exceed the hardness of the jaws can extend their life.

Can the crimping function of the wire stripper handle all terminals?

The crimping function is suitable for specific types of terminals and wires. It is best to check the specifications of the wire stripper to ensure that it is compatible with the terminals to be crimped.

How to reduce the tearing of the insulation layer when stripping wires?

Choose a stripping hole that fits the wire and strip the wire with a steady force. Excessive or uneven force can easily cause the insulation layer to tear.

What should I do if the wire stripper jaws are stuck?

The jaws may be stuck due to residual insulation or rust. The wire stripper can be cleaned regularly and kept dry, and treating the moving parts with lubricants can prevent jamming.

What wires are suitable for the cutting function of the wire stripper?

The cutting function of the wire stripper is suitable for common wires such as copper wire and aluminum wire. For steel wires with higher hardness, it is recommended to use professional wire cutters.

How to choose the appropriate stripping hole diameter?

The stripping hole diameter should match the wire diameter size of the wire. Choosing a hole diameter that is too large or too small may cause incomplete stripping or damage the wire.