Tube Cord End Terminals are mainly used for metal tubular terminals at the ends of wires or cables. They are usually made of copper and tinned to enhance conductivity and oxidation resistance. They can be used to protect the ends of wires to prevent the wires from becoming untied or damaged; improve the connection reliability between wires and terminals, switches or equipment to avoid poor contact; reduce contact resistance and optimize electrical transmission efficiency; and make it easier to insert multi-strand wires into terminal holes, simplify the installation process, and ensure neat and reliable wiring.

Tube Cord End Terminals are made of copper and tinned for excellent conductivity, ensuring efficient and stable current transmission and reducing energy loss. The tinning layer enhances its corrosion resistance, making it particularly suitable for humid or high temperature environments and extending its service life. The high mechanical strength of copper ensures that the terminals can maintain a stable connection under frequent use or vibration environments, while the good solderability makes copper terminals easy to weld with other metal materials to provide reliable electrical connections. In addition, copper is cost-effective, ensuring both performance and economy.

Tube Cord End Terminals adopt tin plating, nickel plating or gold plating and other surface treatments to effectively prevent corrosion from moisture, oxygen, salt spray and other substances, ensuring the stability of the connection. Its anti-oxidation properties further extend the service life of the terminal, especially suitable for high humidity or salt spray environments such as marine, chemical, and automotive. Tube Cord End Terminals with strong corrosion resistance can effectively avoid poor electrical contact and equipment failure caused by corrosion, thereby reducing maintenance costs and ensuring long-term stable operation.

Main application areas

In automotive electrical systems, Tube Cord End Terminals are used to connect components such as batteries, sensors, lights, and engine control units. Its corrosion resistance is particularly suitable for applications where the car is exposed to moisture or salt spray for a long time, ensuring the stability and safety of electrical connections.

Since ships are often in high humidity and salt spray environments, the corrosion resistance of Tube Cord End Terminals makes it an indispensable component in ship electrical systems. They are used to connect power systems, navigation equipment, communication systems, etc., to ensure the stability of electrical transmission and maintain efficient operation even in harsh marine environments.

In industrial automation equipment, Tube Cord End Terminals are mainly used for electrical connection components such as power control, sensors, and controllers. They can withstand harsh environments such as high temperature, humidity, and chemical corrosion, ensuring long-term reliable operation of equipment and reducing failures and downtime.

Tube Cord End Terminals are widely used in electrical connections of electronic equipment, such as home appliances, computer hardware, communication equipment, etc. They provide stable and reliable contact points for connecting cables and equipment, ensuring the stability of signal transmission and power supply.

In the field of solar energy, wind energy and other renewable energy, Tube Cord End Terminals are used to connect power systems and energy conversion equipment, such as photovoltaic panels, wind turbines, energy storage equipment, etc. Their corrosion resistance makes them suitable for electrical connections outdoors or in severe weather conditions, ensuring the efficient operation of energy equipment.

In railway electrical systems, Tube Cord End Terminals are used to connect track signal systems, power supply systems and on-board equipment. Their corrosion resistance enables them to adapt to extreme climate conditions and ensure stable and reliable electrical connections in railway transportation.

In building electrical systems, Tube Cord End Terminals are used to connect various electrical equipment and power lines, such as building automation, lighting systems and emergency power systems. Their anti-corrosion properties ensure the stability of electrical connections in humid or other harsh environments.

In the aerospace field, Tube Cord End Terminals are used to connect aircraft electrical systems to ensure the safe operation of various electrical components inside and outside the aircraft. Since spacecraft often face extreme temperature changes and high-voltage environments, the corrosion resistance and reliability of the terminals are crucial.

In military and defense equipment, Tube Cord End Terminals need to withstand challenges in extreme climate conditions and complex environments to ensure the reliability of electrical connections for various high-tech equipment (such as radar, communication equipment, missile systems, etc.) and reduce failures and delays.

Tube Cord End Terminals are also commonly used for electrical equipment connections in highly corrosive environments such as chemical plants and oil platforms. They can effectively resist the erosion of corrosive gases and chemicals, ensuring the long-term stability of the equipment.

FAQ

How to choose the right size for Tube Cord End Terminals?

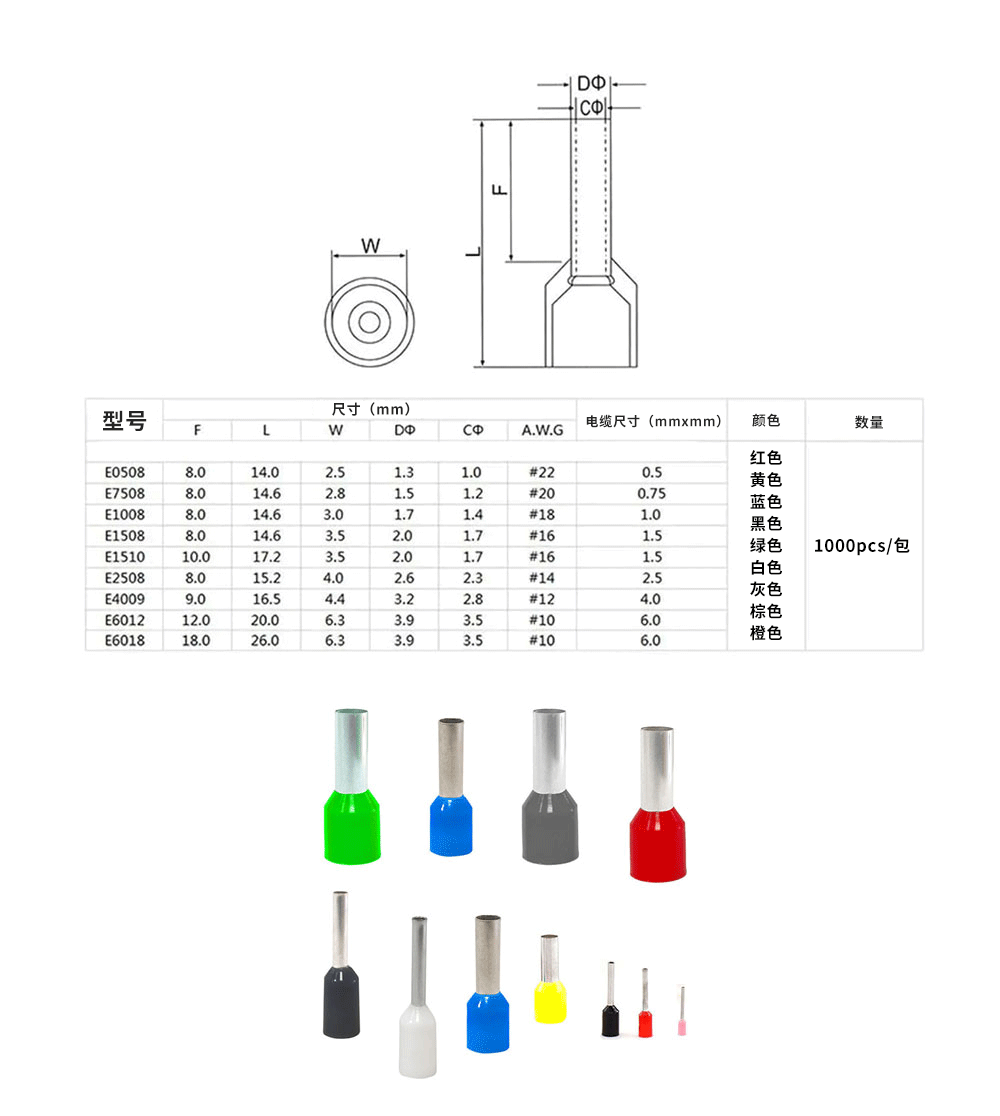

Choosing the right size of Tube Cord End Terminals mainly depends on the cable specifications and the diameter of the conductor. Make sure that the terminal is tightly connected to the cable and meets the rated current requirements. You can refer to the standard size table provided by the cable manufacturer, or choose the appropriate terminal according to the outer diameter and rated current of the cable.

How to ensure that the Tube Cord End Terminals are firmly connected?

Make sure to use the appropriate tools for crimping and operate according to the crimping torque recommended by the manufacturer. During the crimping process, ensure that the terminal is in good contact with the cable conductor and avoid over-crimping or loosening. Regularly check the connection points for signs of looseness or corrosion, and re-crimp or replace the terminal if necessary.

Will Tube Cord End Terminals rust in a humid environment?

Tube Cord End Terminals are usually tin-plated, nickel-plated or gold-plated, which has a certain degree of corrosion resistance. However, corrosion may still occur in particularly humid or salt-fog environments. To extend the service life of the terminal, it is recommended to use terminals with higher corrosion resistance in harsh environments and regularly check the condition of the connection points.

If the Tube Cord End Terminals have poor contact, what are the possible reasons?

Poor contact is usually caused by the following reasons:

Poor crimping: Insufficient or excessive crimping results in poor contact between the conductor and the terminal.

Corrosion: Rust or oxidation on the surface of the terminal or cable conductor increases resistance and affects conductivity.

Wire size mismatch: The terminal size is too small or too large, resulting in an inability to make a tight connection. The solution is to re-crimp, clean the contact surface, ensure that the terminal size is selected, and avoid exposing the terminal to extreme environments.

Are there any problems with using Tube Cord End Terminals in extreme temperatures?

Using Tube Cord End Terminals in extreme temperatures may cause the material to expand or contract, affecting the stability of the connection. In high temperature environments, the terminal material may soften or degrade, resulting in a loose connection; in low temperature environments, the material may become brittle and easily break. Choosing terminals suitable for a specific temperature range and avoiding use in environments outside their operating temperature range can effectively avoid these problems.

How can I clean Tube Cord End Terminals to prevent corrosion?

When cleaning Tube Cord End Terminals, wipe the connection surface with a clean, soft cloth to remove dust, oil or other contaminants. If oxidation occurs, use appropriate metal cleaners and anti-rust oils to ensure that the terminal surface is smooth and corrosion-free. Avoid using overly rough or corrosive cleaning tools to avoid damaging the terminal surface.

How much current can Tube Cord End Terminals withstand?

The current carrying capacity of Tube Cord End Terminals depends on the material, size and design of the terminal. Generally, copper terminals have a higher current carrying capacity, while other materials (such as aluminum) have a lower current carrying capacity. When selecting terminals, it is necessary to determine the appropriate specifications based on the rated current of the cable and the requirements of the working environment.

Does the surface plating of Tube Cord End Terminals affect electrical performance?

The main function of the surface plating of the terminal is to prevent corrosion and maintain good electrical contact. Plating such as tin plating and nickel plating usually does not significantly affect electrical performance, but excessively thick plating may lead to an increase in contact resistance. Therefore, it is very important to choose the appropriate plating thickness to ensure that the terminal can both prevent corrosion and maintain good electrical conductivity.

Can Tube Cord End Terminals be used in high vibration environments?

Tube Cord End Terminals require special attention when used in high vibration environments. Excessive vibration may cause the terminals to loosen or make poor contact. To ensure the stability of the connection, you can choose terminals suitable for vibration environments and use additional fixing measures at the connection, such as locking nuts or using anti-vibration materials to reduce the impact of vibration.